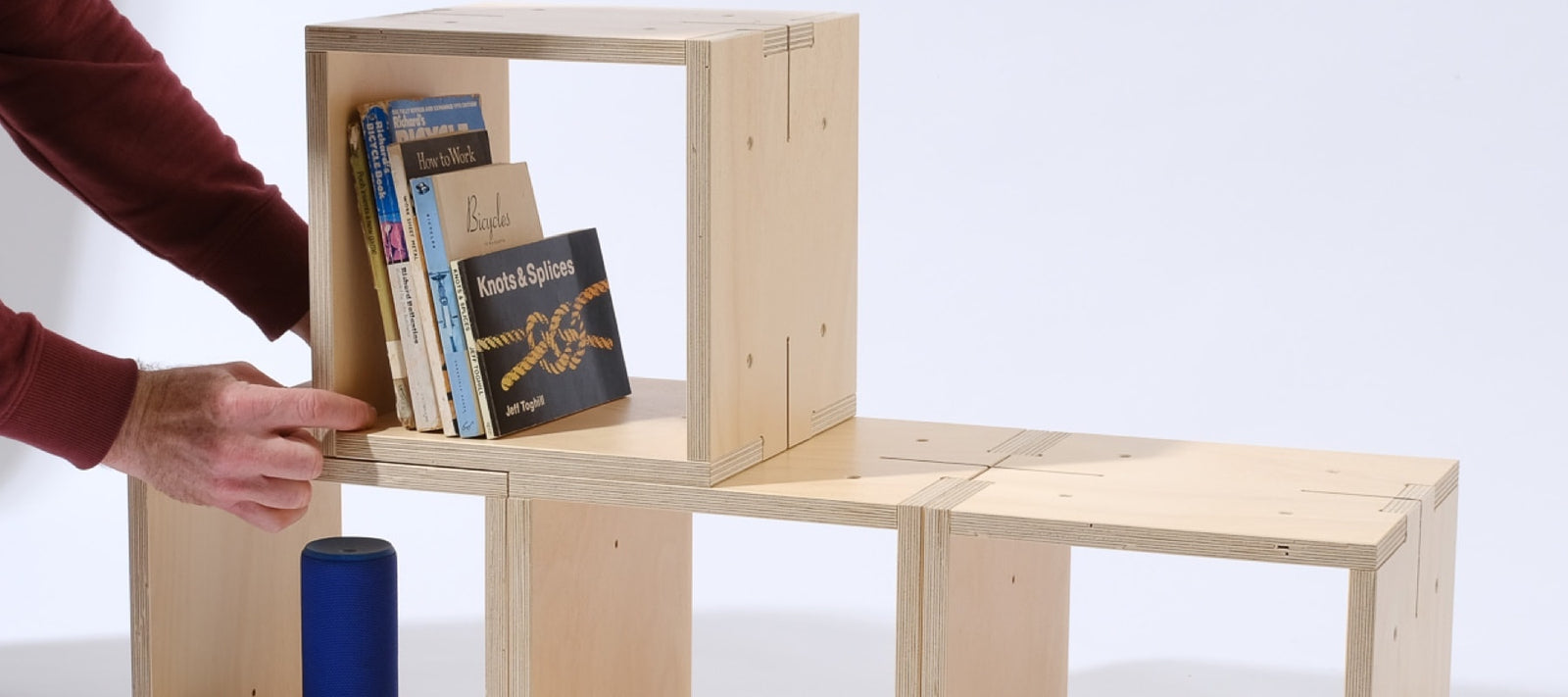

Like Butter Plywood Sawdust Composting Initiative

Background

At Like Butter, we've been experimenting with cold composting our plywood manufacturing waste since 2020. Lab analysis was conducted on mature compost samples aged 18-24 months, showing promising results for transforming workshop waste into valuable soil amendments.

Composting Process

Our current method involves cold composting plywood sawdust in dedicated bays mixed with kitchen scraps, coffee grinds, garden trimmings, and other organic materials with very low intervention. We enhance this process by planting green manure crops on an annual basis, which are then turned back into the compost to add nutrients and improve microbial activity. This passive approach has proven effective but too slow to keep up with production. Our next development phase involves implementing a hot composting system to process our workshop volume more efficiently and accelerate the breakdown cycle.

Laboratory Analysis Results

Positive Findings:

- pH Level: 7.9 (well-balanced)

- Carbon:Nitrogen Ratio: 29:1 (good for soil conditioning)

- Organic Matter: 28% (beneficial for soil structure)

- Total Organic Carbon: 34.7% (excellent for soil health)

- Phosphorus levels suitable for phosphorus-sensitive plants

Areas for Improvement:

- Particle size distribution: Too many particles >16mm

- Moisture content: 25% (slightly below optimal range)

- Physical contaminants: Some glass, metal and rigid plastics detected

Notable Chemical Properties:

- Copper: 314 mg/kg (exceeds AS 4454 limit of 150 mg/kg)

- Zinc: 326 mg/kg (exceeds AS 4454 limit of 300 mg/kg)

- Formaldehyde: 21 mg/kg (within Category D acceptable limits)

- All other heavy metals and organic contaminants well below threshold limits

Expert Assessment

Environmental scientist Bill Grant reviewed our lab results and provided valuable insights:

The elevated zinc and copper levels, while exceeding standard compost guidelines, could be beneficial in specific applications where soils are deficient in these elements. He noted these levels are the only concern, as other macro-nutrients appear well-balanced.

Mr. Grant suggested our compost could be particularly useful in:

- Areas with zinc and copper deficiencies

- Cropping and pasture systems at lower application rates

- Orchards and ornamental gardens

He advised against use in daily-harvest vegetable gardens and recommended clear labelling regarding metal content if commercialised.

Future Directions

-

Process Refinement:

- Implementing hot composting to increase throughput

- Improving screening to reduce physical contaminants

- Optimising moisture content and particle size

-

Application Development:

- Creating specific blends for targeted soil improvement

- Testing in controlled growing environments

- Monitoring long-term soil impacts

-

Industry Collaboration:

- Sharing findings with other manufacturers

- Exploring collective waste management solutions

- Developing best practices for timber waste valorisation

Conclusion

Our plywood sawdust composting initiative demonstrates promising potential for closing the loop in our manufacturing process. While some parameters require refinement, the results validate our approach to transforming workshop waste into a valuable resource with specific agricultural applications.

This project represents Like Butter's commitment to sustainable manufacturing practices and our ongoing efforts to reduce environmental impact while creating value from production by-products.

cam robbins

April 08, 2025

great work Jem thanks

for sharing , fascinating reading all the chemistry results . the compost must be

better

than a lot of soils

around the

goldfields