Jem Selig Freeman - Director

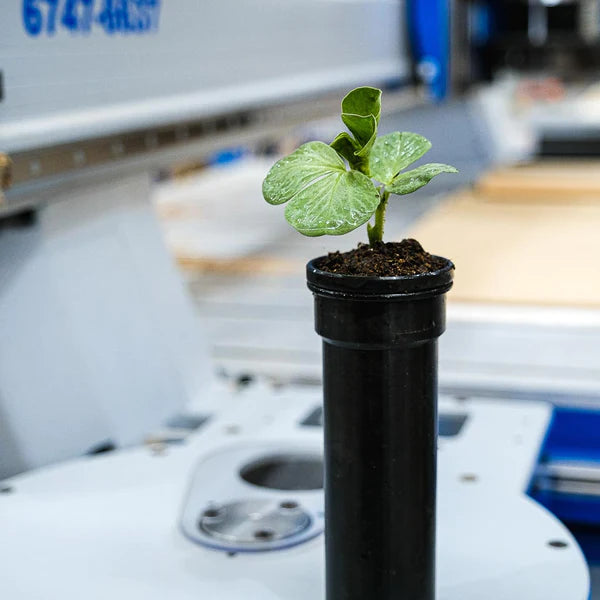

We're happy to announce that Like Butter has achieved carbon neutrality in many aspects of our manufacturing, including our use of electricity, water, paper, waste,vehicles. (Financial year 2021-2022)

Our 33kWh rooftop solar system powers our workshop and machinery. Any remaining supply is offset with certified 100% carbon offsets.

Sustainability is not an afterthought; it’s woven into the fabric of everything we do.

We’re boldly taking steps towards zero waste and carbon-neutral manufacturing. We believe that achieving this goal is possible and necessary in our pursuit of creating a sustainable and resilient business model.

We place people before profit. We've been operating Monday-Thursday since 2017, aiming to create a healthy work-life balance. We believe in making space for life, knowing that a content team is a productive team.

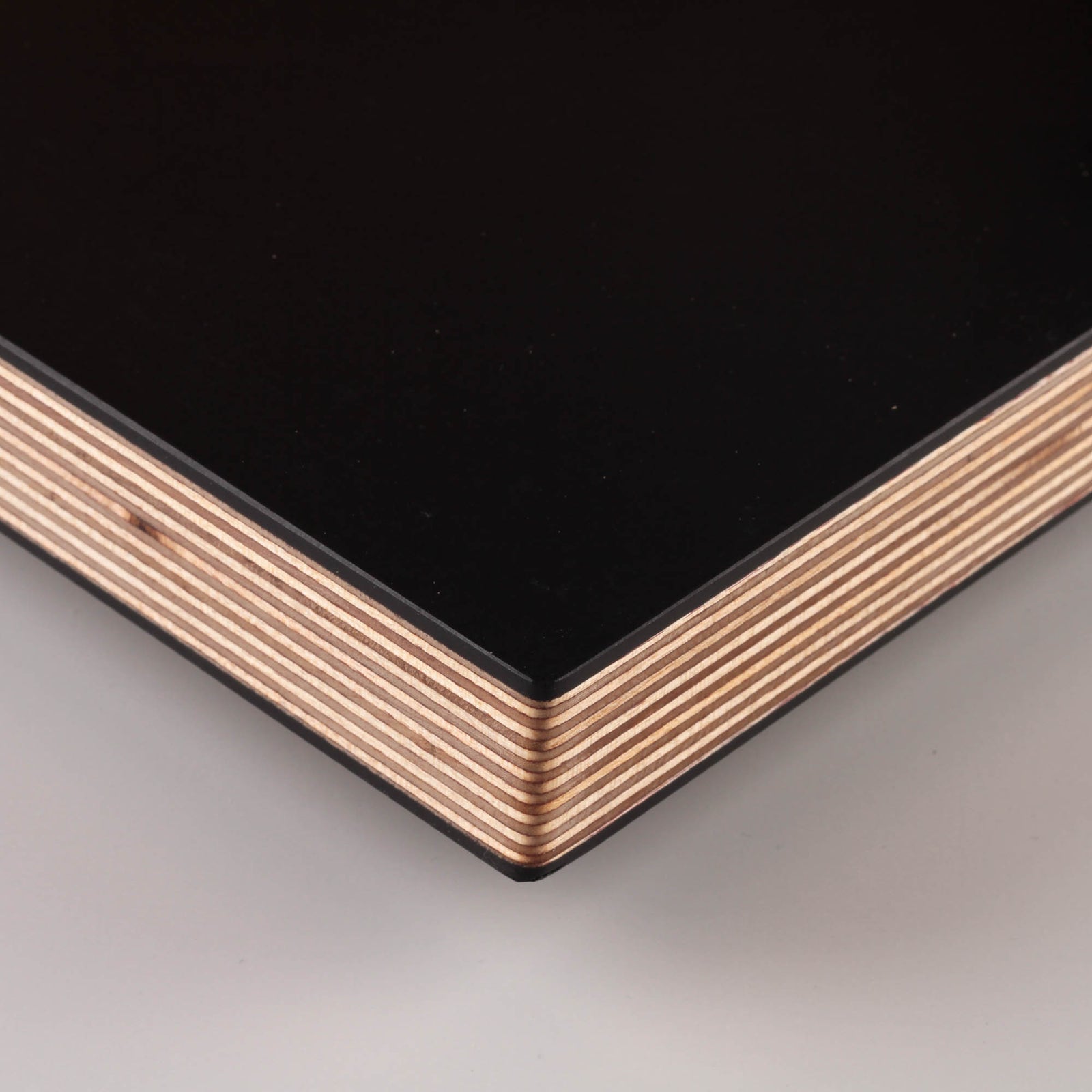

Guided by our vision statement, we're committed to sustainability and circular economy principles. We proudly use locally sourced, Australian-grown Hoop Pine (57% of all of our material usage) and responsibly managed hardwoods (14%). We're aiming to progressively use more reclaimed timber and lessen our reliance on virgin stock.