Our two Multicam machines, meet Cameron, a powerful HSD milling spindle with vacumm hold-down and Trinity who can do everything Cameron can do but faster and with knives for cardboard and felt cutting.

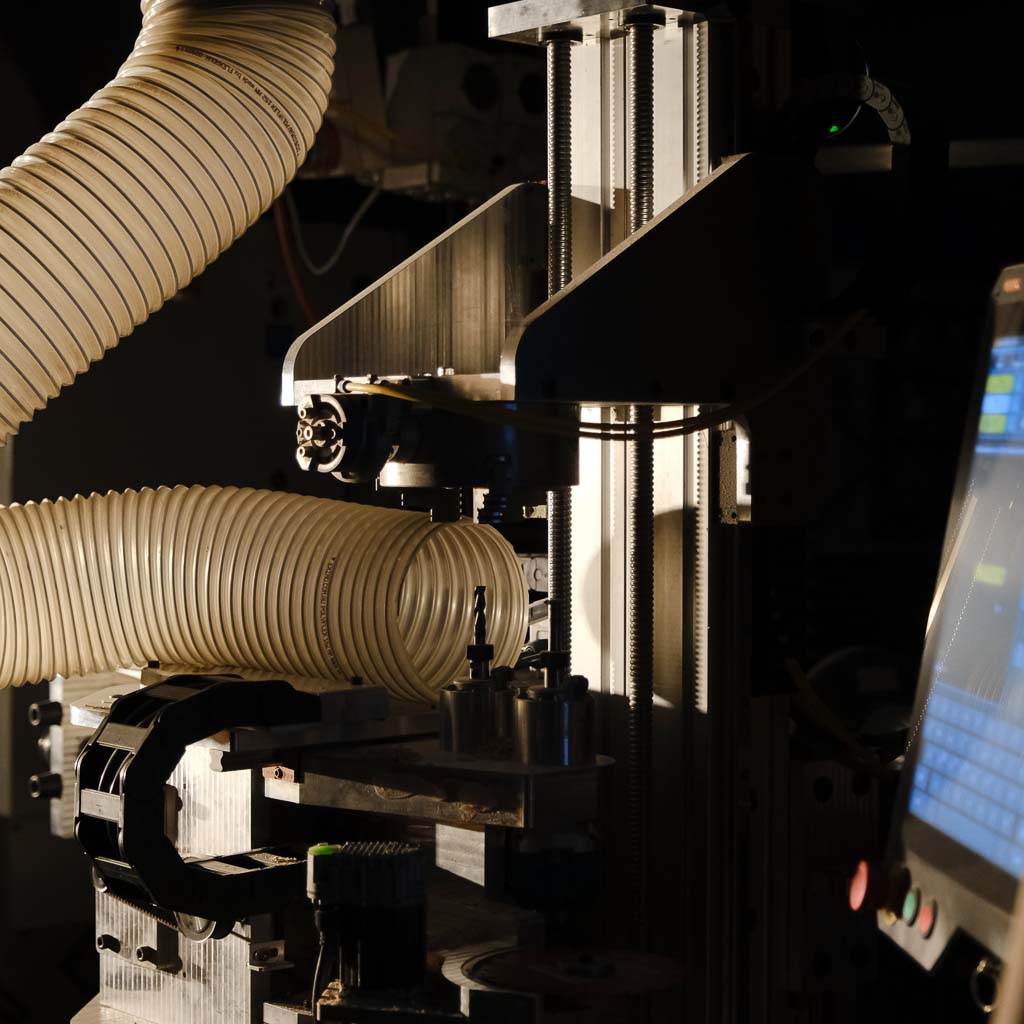

Our custom-built, one-of-a-kind, 4-axis CNC milling machine for making our threaded timber products.

?

We'll work with you to determine the appropriate tolerance range for your parts. +-0.1 mm etc

Our professional HSD spindles handle deep cuts at high feedrates.

We've been CNC machining timber parts for 15 years with a continuous improvement ethos.

Our machines are powered by a 33kW rooftop solar array. Making our operation carbon neutral.

TECH SPECS

Read on to be that person who supplies us with world-class CNC ready files.

Machining

Oscillating Tangential Knives

Specialist ('The Pencil Sharpener')

Typical machine setup:

2440 x 1220mm with vacuum hold down bed

Maximum machine travel:

2751 x 1590 x 90mm (XYZ)

If you're providing nested sheets, please supply them within a single file. Separate layers for each machine operation type is preferred but not essential. We can draw up and program files as per your specifications, a dimensioned sketch is often enough for simple jobs.

Please note that our minimum CNC machining quote is $1,200. We have limited capacity to machine other people’s parts, but we are happy to look at your files and give you a quote, bearing in mind our minimum for this sort of work.

Please submit a quote request with details and files via the form below.